- Power Tools

-

Saws

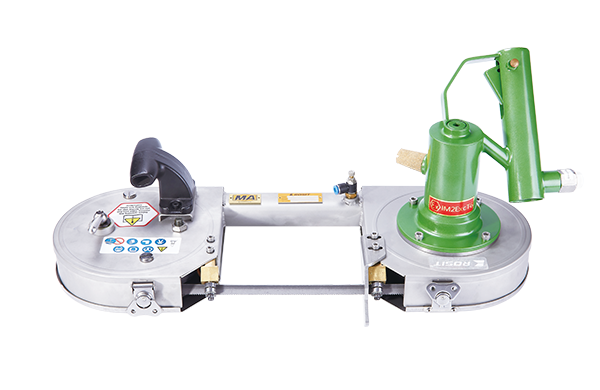

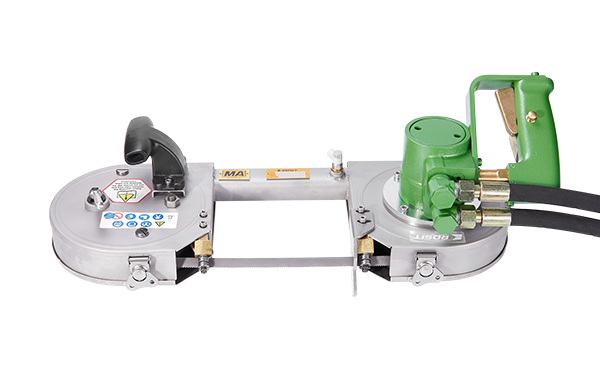

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

MENU

Pneumatic Torque Wrench

Description

Application

Ideal for removing and installing nuts and bolts of equipment; Applied in mining, ships, power plants, wind power generation, hydro power, nuclear power, petrochemical and other fields.

Features

● Constant torque output:

No reacting force to avoid destructive nut hammering.

● Optional Bluetooth and Wireless module:

Connected with c-series sleeves to achieve sensor verification joint calibration and accurate control and track of torque output. (Customized).

● The enclosed lightweight aluminum alloy housing provides stable torque output:

Torque output accuracy ±4% and repetition accuracy ± 2%.

● Heavy industrial grade durable motor:

Ensures the continuity of torque output and the long-term stability of motor power and provides a reliable and durable solution for the installation and removal of heavy nuts.

● Optional digital display adjusts torque every 10Nm:

More accurate selection of target torque (customized).

● Optional sensor system:

Target unit of torque output is precisely controlled which is up to±2% (customized).

● Ergonomic designed handle:

Injury and fatigue of operators are reduced, and the production efficiency is improved.

● Light tool basket:

More convenient working sites.

You are here: >

You are here: >