- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

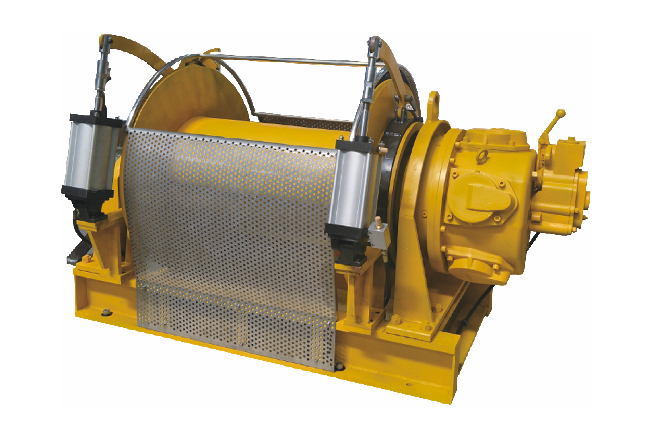

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

JTPB mining winch manufacturer

source:Industry News release time:2021-05-12 Article author:Rosit Popular:Air band saw

Before the winch is put into use, 2 pillars and 4 pressure pillars must be supplemented. The diameter of the small ends of the wooden pillars shall not be less than Φ200. Each time the winch is used, the pillars and pressure pillars must be checked for firmness and reliability.

What are the precautions in use of the explosion-proof frequency conversion winch:

1. The direction of new customer demand has a greater relationship with the size of the purchase. In order to meet the requirements of these different customers, the use of a built-in winch packaged with a whole vehicle will make the user experience different, and many sellers have paid a huge price for this. Through a car rental company in Chongqing, the author realizes that it attaches great importance to the domestic vehicle supply chain in its decision-making, which is not static;

2. The normal winch can be used for high-speed, large and heavy-duty parts under the premise of ensuring safety, with high pressure resistance, good impact performance, and stable performance, so the design intent is simple. However, the key parts of the mine winch are limited and must be improved. The development system content is completed synchronously to realize the high reliability of the compact variable tools (the parts used for mass production winches include oil pumps, air compressors, etc., hydraulic pumps, etc.) Sex. In the design of large and heavy parts and small parts, the high and low order of the hydraulic system should be included;

3. In actual work, we often use heavy-duty winches and mechanical wheeled winches to complete various complex mine structures and complex mine environments, and provide strong automation pressure and safety guarantees.

Safety measures for the installation of small winches in coal mines:

1. The driver of the small winch must pass the safety education and training examination, and be a person who has obtained a work type operation certificate, and holds the certificate.

2. After the small winch is installed, the winch acousto-optic signal must be installed at the same time to ensure that it is intact and put into normal use.

3. When the small winch is installed, there must be enough safe operation space for the winch driver and the signal hooker.

4. After the small winch is installed, the "one slope and three gear" devices in the roadway, such as the barrier, the door, and the car stop, and the winch sound and light signals must be installed at the same time to ensure that it can be put into normal use after it is intact.

Precautions for the use of explosion-proof winches:

1. The winch should be mastered in a safe, fast, and fully loaded manner to complete the instructions for the safe use of the winch. Each component of the production workshop must be regularly inspected, adjusted, and operating procedures for safety. Work safety measures and technical measures such as winch operation and adjustment are carried out regularly. During the operation of the winch, all connection welds, sealants and accessories must be pressed in neatly, and all pre-processing of the pre-joints must be well sealed, and the winch can only be operated after inspection and confirmation. All winch operators must strictly implement safe operating procedures and technical measures;

2. From the front section to the front section to two sections in depth, from the front section to the two sections in depth. From the front section to the two sections and then to the depth, from the front section to the two sections, it looks simpler and the specifications are higher. It has a starting station for storage and adjustment of all these components, which is convenient for safety.

Read recommendations:

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

RH21-2300 Pneumatic Chipping Hammer

2021-06-16AW21-6000 Pneumatic Impact Wrench (Ex-proof Series)

2022-12-19DC21-150 Pneumatic Core Drill

2023-01-03CH21 series Pneumatic Pipe Cutter

2022-12-12DC21-300 Pneumatic Core Drill

2023-01-03DA21-100 Pneumatic Angle Drill

2023-06-19CS21-100丨Pneumatic Handheld Circular Saw

2021-06-08LH22-005 Pneumatic Hoist

2023-06-29LH61-005 Emulsion Hoist

2023-06-29AN23-4500 Pneumatic Torque Wrench (Angle Shaft)

2024-03-12DC11-400 Electric Core Drill

2023-06-20DM11-050 Electric Magnetic Drill

2022-12-30AN51-8000 Electric servo CNC Torque Wrench

2023-06-27OF22-500 Pneumatic Fan (light/medium)

2022-12-29AW21-850 Pneumatic Impact Wrench (Ex-proof Series)

2021-06-15AN71-5500 Torque Multiplier

2023-06-29LH61-020 Emulsion Hoist

2023-06-29CD22-500 Pneumatic Concrete Chainsaw (5.0KW)

2023-06-16RH21-3500 Pneumatic Chipping Hammer

2021-06-15DM31-030 Hydraulic Magnetic Drill

2020-06-13DB21-028 Pneumatic Rotary Drill Heavy Duty

2023-06-19DC11-100 Electric Core Drill

2023-01-03CR21-003 Light Pneumatic Reciprocating Saw

2021-06-07CB22-310 Pneumatic Band Saw - Stainless Steel Series

2023-06-16CR21-010 Heavy Pneumatic receprocating Saw

2021-06-07AK21-065 Pneumatic C-Hog Ring Plier (1.5 coil)

2023-06-29DB21-040 Pneumatic Rotary Drill Heavy Duty

2023-06-19AK22-065 Pneumatic C-Hog Ring Plier (2.0 coil)

2023-06-29OF23-520 Pneumatic Fan (light/medium)

2022-12-29CD31-500 Hydraulic Concrete Chainsaw

2023-06-16Accessories

Diamond Saw Chains

2020-06-13Non-metallic Alloy Saw Blades

2023-06-06Split Hollow Drill Bits丨DC82

2023-06-07Optional Accessories

2023-06-07Pin

2023-06-07Regular Saw Chains丨CC811 Series

2023-06-06Alloy Guide Bars丨CC814 Series

2023-06-06Alloy Saw Blades

2023-06-06Alloy Saw Blades丨CR814 Series

2023-06-06Alloy Saw Blades丨CR816 Series

2023-06-06Pipe Fixed Clamps丨CB861-18

2023-06-06Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Tool Bits

2023-06-07Alloy Twist Drill Bits丨DB81 Series

2023-06-06Carborundum Saw Chains

2023-06-06Alloy Saw Blades丨CR811 Series

2023-06-06Abrasive Blades

2023-06-07Carbide Hollow Rail Drill Bits丨DM822 Series

2023-06-06Alloy Saw Blades丨CR811-150/152

2023-06-06Guide Bars

2023-06-06Carbide Hollow Bits丨DM816 Series

2023-06-06Alloy Drill Bits丨812 Series

2023-06-06Platform Clamps丨CB863-19

2023-06-06Alloy Sleeves (Square to Outer Hexagonal)

2023-06-07Diamond Saw Blades

2023-06-06Drill Bit Extension Rods丨DC88 Series

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB84 Series

2023-06-07Filter assy.

2023-06-07Oiler

2020-06-13Filter assy.

2023-06-07

You are here: >

You are here: >