- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

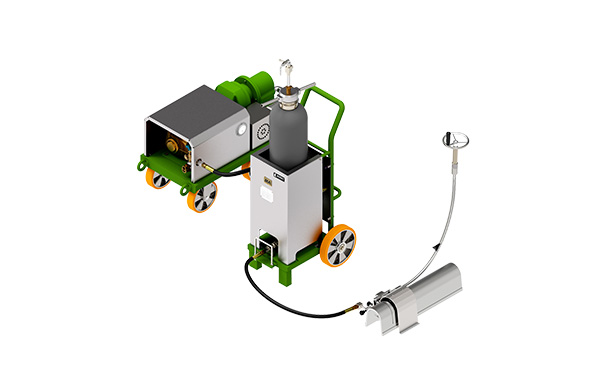

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Tool Maintenance

Guidance on pneumatic tools maintenance

The owner or operator must have the maintenance habit so that the working life will be longer. Sometimes, the damages are caused because of no maintenance or being without knowledge of maintenance.

Every time before using or operating, please drip 3-4 drops of oil to lubricate the machine to reduce the abrasion.

Better to add a filter for the air supply machine to provide the dry, purified air, and add oil for lubricating, and adjust the appropriate working pressure. Replace the damaged parts, brush some anti-rust oil to protect rusty and block the air inlet and other inlets to prevent the dirt into the machine.

When using or operating the tools, please don’t work over its maximum pressure. When replacing the tools or parts, please remove it first from the air supply machine. When working or operating, please wear the protective glasses, ear-blocks, mask to keep yourself safe. When operating, please don’t wear the causal large clothes, scarf, tie or jewelry in order not to be rolled into the machine. When connecting with the high pressure air supply machine, you are not supposed to press the wrench before working.

All the parts are supposed to be in good condition any time, therefore it will be dangerous if there is a loosen part. When replacing the worn-out parts, please use the professional parts. Please don’t point at yourself or at others when operating any machine.

Safety instructions

Check the air supply pipeline and the connector to see if there is any air leaking place. The air inlet should seal well and the switch should be flexible. All the air circuit should be without air leaking problem.

If there is corrosion, leaking, bulge phenomenon, please replace the part immediately. Checking if all the parts are in good conditions or not. If so, please replace it as soon as possible.

Check the rotating speed and condition and for impact tools. Ensure the loosen parts are in good condition.

Contact us

ROSIT GmbH

- Email: info@rosit.eu

- Tel: +49 69 6780 8096 Fax: +49 69 6780 8326

- Add: Lyonerstr.34 Turm 2 Stock 8 60528 Frankfurt am Main, Deutschland

You are here: >

You are here: >