- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

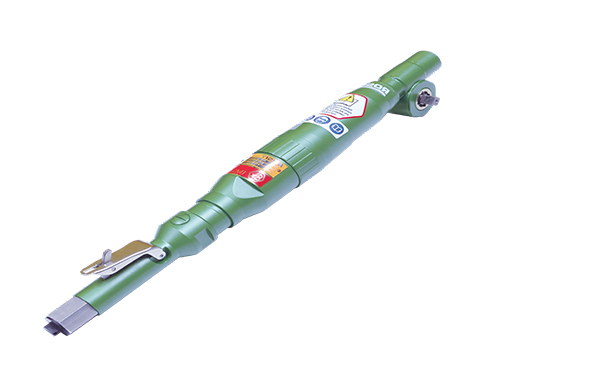

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Failure Detection of Hydraulic Tool Hydraulic Wrench System

source:Industry News release time:2021-11-13 Article author:Rosit Popular:Air band saw

There are many diagnostic methods for hydraulic wrench switch failures, but the most commonly used is sensory diagnosis. Sensory diagnosis method is to rely on equipment maintenance personnel to use simple diagnostic equipment and personal operating experience to diagnose the failure of the hydraulic switch, and determine the location and cause of the failure. For some simple faults of hydraulic wrenches, we can check the parts by seeing, touching, hearing and smelling.

(1) Visual diagnosis method

It is to use eyes to detect the operation of the hydraulic wrench switch, to detect the pressure value and temperature change of each pressure measurement point of the hydraulic switch, and to check whether the oil is clean and whether the amount of oil is sufficient. Check whether there is oil leakage at the hydraulic valve and pipe joints, the end cover of the hydraulic cylinder, and the drive shaft of the hydraulic pump. Hydraulic wrenches Detect products processed from equipment or perform performance tests to identify the operating status of the motion mechanism, the stability of the pressure and flow of the switch, and the operating status of the solenoid valve.

(2) Auditory diagnosis method

Use your ears to judge whether the operation of the hydraulic wrench, the switch or the component is normal, etc. Listen to whether the noise of the hydraulic pump and the hydraulic switch is too loud; listen to whether there are abnormal sounds from components such as the overflow valve; listen to whether the impact sound of the operating platform is too loud; listen to whether the piston collides against the bottom of the hydraulic cylinder, etc. .

(3) Tactile diagnosis method

Touch the temperature and operating status of the moving parts of the hydraulic wrench by hand, and touch the temperature of the hydraulic pump casing, the outer wall of the oil tank and the valve body casing by hand. The normal temperature should be around 55°C, if it exceeds 60°C, the cause should be checked. Hydraulic wrench Touch the moving parts and oil pipes with your hands, and feel for obvious vibration.

(4) Olfactory diagnosis method

Use your nose to sniff the hydraulic wrench oil to see if there is a peculiar smell. If you smell the scorched odor of the hydraulic oil, it means that the hydraulic pump and other hydraulic components are locally heated, causing the hydraulic oil to be burnt and smoke. Based on this, you can judge the heating part. Hydraulic Wrench Check whether the hydraulic oil has a foul smell or a pungent spicy smell. If it does, it means that the hydraulic oil has been severely contaminated and needs to be replaced and repaired in time. It can no longer be used.

Read recommendations:

CN21-1424 Nut Cutter丨Manual Integrated Nut Cutter

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

AN31-1800 Hydraulic Torque Wrench

2022-12-27CB31-260 Hydraulic Band Saw

2023-06-16LH31 Series Hydraulic Hoist

2023-05-11AW41-1500 Emulsion Impact Wrench

2020-06-13RH31-2100 Hydraulic Chipping Hammer

2022-12-27CD22-630 Pneumatic Concrete Chainsaw (5.0KW)

2023-06-16LH61-003 Emulsion Hoist

2023-06-29CN22-70115 Nut Cutter丨Split-type Nut Cutter

2022-12-12CB61-260丨Emulsion Band Saw

2023-06-17DA21-050 Pneumatic Angle Drill

2023-06-19AK22-030 Pneumatic C-Hog Ring Plier (2.0 coil)

2022-12-12AW22-6000 Pneumatic Impact Wrench (Ultra-Light Series)

2021-06-15RH31-1000 Hydraulic Chipping Hammer

2023-06-27OW65-020 Split Emulsion Type Mining Waterjet Cutting Machine

2023-05-10AW22-750 Pneumatic Impact Wrench (Ultra-Light Series)

2022-12-20RH21-1450 Pneumatic Chipping Hammer

2021-06-16CB11-120 Electric Band Saw

2020-06-13LH61-020 Emulsion Hoist

2023-06-29AK71-130 Manual C-Hog Ring Plier (1.5 coil)

2022-12-12DB21-050 Pneumatic Rotary Drill Heavy Duty

2023-06-19CN22-110130 Nut Cutter丨Split-type Nut Cutter

2023-06-17DL21-016 Pneumatic Pistol Hammer Drill

2021-06-10CD22-250 Pneumatic Concrete Chainsaw (5.0KW)

2020-06-13GG11-230 Electric Angle Grinder

2023-06-28DM21-023 Pneumatic magnetic drill

2021-06-15AW22-4000 Pneumatic Impact Wrench (Ultra-Light Series)

2021-06-15AN31-10000 Hydraulic Torque Wrench

2023-06-27OF27-100 Heavy Fixed Fan

2022-12-29DH21-050 Pneumatic Hammer Drill

2021-06-10CR21-003 Light Pneumatic Reciprocating Saw

2021-06-07Accessories

Alloy Drill Bits丨811 Series

2023-06-06Drill Bit Extension Rods丨DC88 Series

2023-06-07Carbide Hollow Rail Drill Bits丨DM822 Series

2023-06-06Alloy Saw Chains丨CC812/CC816 Series

2023-06-06Alloy Saw Blades丨CR811-150/152

2023-06-06Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Alloy Saw Blades

2023-06-06Alloy Twist Drill Bits丨DB81 Series

2023-06-06Diamond Saw Chains丨CC813 Series

2023-06-06Alloy Saw Blades丨CR811 Series

2023-06-06Tool Bits

2023-06-07Carbide Inserts Twist Bits assy.丨DB83 Series

2023-06-07Diamond Saw Blades

2023-06-06Pipe Fixed Clamps丨CB861-12

2023-06-06Core Drill Morse Taper Sleeves

2023-06-07Alloy Saw Blades丨CR812 Series

2023-06-06Cutting Blades

2023-06-07Carbide Hollow Bits丨DM816 Series

2023-06-06Hydraulic Pump Station

2023-06-07Split Hollow Drill Bits丨DC82

2023-06-07Chisels

2023-06-07Filter assy.

2023-06-07Water Pump

2020-06-13Diamond Saw Chains

2020-06-13Platform Clamps丨CB863-19

2023-06-06Rail Clamps丨CB864-12

2023-06-06Integrated Hollow Drill Bits丨DC81

2023-06-07Shovel Blades

2023-06-07Carborundum saw Blades

2023-06-06Hydraulic Regulating Valve

2023-06-07

You are here: >

You are here: >