- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Characteristics and precautions of driving hydraulic wrench

source:Industry News release time:2022-09-17 Article author:yu Popular:Air band saw

Drive hydraulic wrench, there is no limit to the height, and the support point cannot be found. This type of wrench can be used in the working conditions without limited angle space, and the range of use is wide. In order to facilitate everyone's use, Zhonghong Precision will introduce the characteristics of the driving hydraulic wrench and the precautions for use.

1. Features of driving hydraulic wrench:

1. Jinghong hydraulic wrenches are all made of aviation aluminum-titanium alloys, with a one-piece body, light weight, good toughness and long service life.

2. The working pressure is 70MPa, and it works by matching the high and low pressure of the oil pump (for specific parameters and pressure values, please consult Jinghong hydraulic wrench).

3. The reaction force arm is 360° fine-tuned to find the support point. The force arm sheath is made of titanium alloy steel, which has high strength, heat resistance and corrosion resistance.

4. The oil pipe joint that can be rotated 360°×180° has no space limitation and can be operated freely.

5. The precision ratchet is used to prevent jamming, and the accuracy is as high as ±3%.

6. 12 different specifications and models, a variety of colors are available.

7. The drive shaft is made of special material, with high strength, and it is easy to switch the direction of loosening and tightening.

Second, the use of driving hydraulic wrench matters needing attention:

1. The quick joint of the high-pressure oil pipe connection wrench must be in place, and no gaps can be left, otherwise the poor oil circuit will cause the wrench to not work, and it will also cause the pressure joint of the oil pipe to be unable to be removed smoothly;

2. When the wrench is working, make sure that the sleeve acting on the wrench matches the nut, and the reaction arm finds the support point;

3. Before the wrench is used, the drive shaft needs to be inserted into the ratchet and twisted clockwise to ensure that the pawl and the ratchet are in complete agreement;

4. When disassembling and assembling the quick joint, be sure to keep the inside and outside of the joint clean to avoid dust and sand entering the oil circuit and causing the sealing ring to wear, thereby reducing the service life of the hydraulic wrench.

commun antenna custom

Read recommendations:

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

LH22-005 Pneumatic Hoist

2023-06-29DM11-100 Electric Magnetic Drill

2023-06-19CR21-012 Heavy Pneumatic Reciprocating Saw

2021-06-07RH21-2500 Pneumatic Chipping Hammer

2021-06-15DB21-025 Pneumatic Rotary Drill Heavy Duty

2023-06-19LH61-032 Emulsion Hoist

2023-06-29RH31-1400 Hydraulic Chipping Hammer

2023-06-27AN23-8000 Pneumatic Torque Wrench (Angle Shaft)

2024-03-12AN31-20000 Hydraulic Torque Wrench

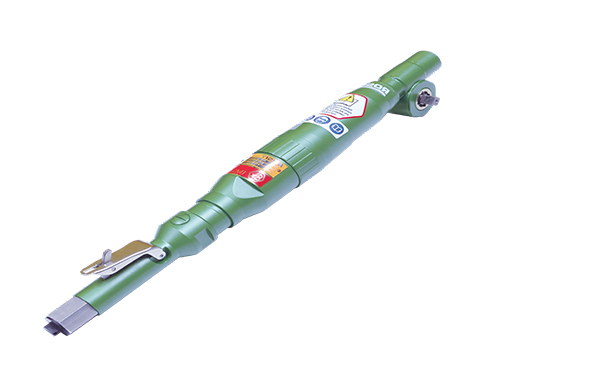

2023-06-27AN22-2500 Pneumatic Torque Wrench (Straight Shaft)

2023-06-27DB21-022 Pneumatic Rotary Drill Heavy Duty

2023-06-19CB21-200 Pneumatic Band Saw - Aluminum Alloy Series

2023-06-16DC11-150 Electric Core Drill

2023-06-20CC23-530 Pneumatic Chainsaw Heavy-Duty (3.5KW Series)

2023-06-14CB22-160 Pneumatic Band Saw - Stainless Steel Series

2023-06-16CN22-110130 Nut Cutter丨Split-type Nut Cutter

2023-06-17DB21-018 Pneumatic Rotary Drill Heavy Duty

2020-06-13LH61-015 Emulsion Hoist

2023-06-29LW21-005 Pneumatic Winch

2023-01-06LH61-001 Emulsion Hoist

2022-12-29AN31-10000 Hydraulic Torque Wrench

2023-06-27CN22-1924 Nut Cutter丨Split-type Nut Cutter

2023-06-17DH21-050 Pneumatic Hammer Drill

2021-06-10LH22-010 Pneumatic Hoist

2023-06-29DM11-050 Electric Magnetic Drill

2023-06-19CC20-380 Pneumatic Chainsaw

2020-06-13CB31-160 Hydraulic Band Saw

2023-06-16CH11 Series丨Electric Pipe Cutter

2022-12-12LH22-003 Pneumatic Hoist

2023-05-11OW65-020 Split Emulsion Type Mining Waterjet Cutting Machine

2023-05-10Accessories

Hard Alloy Hollow Drill Bits assy.丨DB84 Series

2023-06-07Integrated Hollow Drill Bits丨DC81

2023-06-07Alloy Twist Drill Bits丨DB81 Series

2023-06-06Hard Alloy Hollow Drill Bits assy.丨DB85 Series

2023-06-07Diamond Saw Chains丨CC813 Series

2023-06-06Alloy Drill Bits丨811 Series

2023-06-06Diamond Saw Chains

2020-06-13Core Drill Morse Taper Sleeves

2023-06-07Filter assy.

2023-06-07Carborundum saw Blades

2023-06-06Cutting Blades

2023-06-07Ex-proof Sleeves

2023-06-07Alloy Saw Blades丨CR811 Series

2023-06-06Split Hollow Drill Bits丨DC82

2023-06-07Grinding Disc

2023-06-07Abrasive Blades

2023-06-07Sleeve KIT

2023-06-07Alloy Saw Blades丨CR812 Series

2023-06-06Alloy Drill Bits丨812 Series

2023-06-06Non-metallic Alloy Saw Blades

2023-06-06Clamps

2023-06-06Filter assy.

2023-06-07Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Diamond Saw Blades

2023-06-06Optional Accessories

2023-06-07Carbide Hollow Bits丨DM816 Series

2023-06-06Alloy Drill Bits丨813 Series

2023-06-06Alloy Saw Blades丨CR814 Series

2023-06-06Alloy Saw Blades

2023-06-06Tool Bits

2023-06-07

You are here: >

You are here: >