- Power Tools

-

Saws

Chain Saw Concrete Chain Saw Band Saw Reciprocating Saw ...

-

Cutters

Pneumatic Cutter Pipe Cutting Machine Nut Cutter

-

Drills

Hammer Drill Pistol Hammer Drill Two Hand Operation Drill Column Drill ...

-

Impact Wrenches

Pneumatic Impact Wrench (Ex-proof Series) Pneumatic Impact Wrench (Ultra light Series) Emulsion Impact Wrench Nut Runner ...

-

Torque Wrenches

Pneumatic Torque Wrench Electric Torque Wrench Hydraulic Torque Wrench Hollow Hydraulic Wrench ...

-

Mining Waterjet Cutting Machine

Electric Mining Waterjet Cutting Machine Pneumatic Mining Waterjet Cutting Machine Emulsion Mining Waterjet Cutting Machine

-

Hammers

Pneumatic Chipping Hammer Hydraulic Chipping Hammer

-

Scaler

Pneumatic Long Reach Scaler

-

Rammer

Pneumatic Rammer

-

Grinders

Wet Grinder Angel Grinder Electric Grinder

-

Fan

Pneumatic Fan Heavy Fixed Fan

-

Hoist

Chain Hoist Electric Hoist Pneumatic Hoist Hydraulic Hoist ...

-

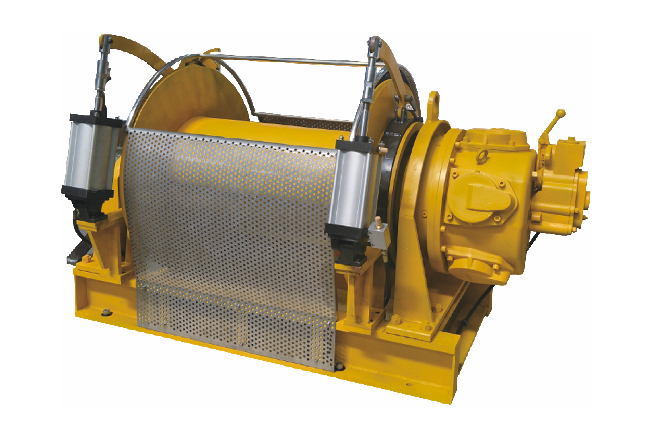

Winch

Pneumatic Winch

-

Pump

Pneumatic Submersible Pump Emulsion Submersible Pump

-

Assembly

Torque Multipler C-Hog Ring Plier

-

- Accessories

-

Cutting

Chainsaw Concrete Chainsaw Band Saw Reciprocating Saw ...

-

Drilling

Impact Drills Light Drills Magnetic Drills丨Rail Drills Balance Drills丨Angle Drills ...

-

Assembly

Impact Wrenches C-Hog Ring Plier

-

Hammer & Shovel

Chipping Hammer Derusting Shovel

-

Grinding

Grinders

-

Hydraulic Accessories

Nut Runner Cutter

-

General Accessories

Waterjet Cutting Machine Filter assy. Filter assy. Water Pump ...

-

- Company Profile

- Service

- News

-

Events

The 21st 2023 Taiyuan Coal (En The 17th Yulin International C The 20th TaiYuan (2021) Coal ( The 16th Ordors International Have a machine repaired or hav ...

-

Case Study

Specifications of adjustable w Have a machine repaired or hav

-

Industry News

Using Chainsaws to Cut Snow? What to do if the pneumatic wr Hydraulic chain saw Operation of the wrench Introduction to the principle ...

-

- Download

- Contact

Winches operating rules

source:Industry News release time:2021-05-12 Article author:Rosit Popular:Air band saw

The winch driver must operate strictly in accordance with the operating procedures and drive: the winch cannot be opened when it is not intact; the wire rope is worn out, the broken wire exceeds the limit and the knot cannot be opened; the safety facilities and signals are incomplete, and the unknown is not opened; the object is overweight and the roadway support Endanger the safety of operation.

The explosion-proof mine winch is closer to the base structure than the ordinary sand-coated copper explosion-proof rope, and has another versatility. The high-pressure turbine shaft, ring intermediate shaft, lower rotor shaft and other explosion-proof sliding molds can be directly coupled to the flame. The device constitutes a complex tensile component.

Safety measures for the installation of small winches in coal mines:

1. The driver of the small winch must pass the safety education and training examination, and be a person who has obtained a work type operation certificate, and holds the certificate.

2. After the small winch is installed, the winch acousto-optic signal must be installed at the same time to ensure that it is intact and put into normal use.

3. When the small winch is installed, there must be enough safe operation space for the winch driver and the signal hooker.

4. After the small winch is installed, the "one slope and three gear" devices in the roadway, such as the barrier, the door, and the car stop, and the winch sound and light signals must be installed at the same time to ensure that it can be put into normal use after it is intact.

Safety technical measures for winch transportation

1. The installation and fixation of the small winch, and the fastening of the anchor bolts.

2. For the small winch brake, the brake band must be intact and not broken, and the wear should not exceed the limit.

3. Check the arrangement of the wire ropes on the drum and the integrity of the wire ropes. They must be neatly arranged, no ropes, and no hard bends, broken wires, knots, etc. In particular, check the condition of the hook head (sweet heart ring) and the wire rope within 30 meters of the hook head.

4. Test whether the signal system is sensitive and reliable, and the sound is clear.

5. The fixed and intact conditions of the stopper and the stopper.

6. During the operation of the winch, the system of "no pedestrians in traffic and no pedestrians in traffic" must be strictly implemented in the roadway.

7. The winch driver must be trained and passed the examination before he can work with a certificate.

8. All lifting vehicles must carry out the number of vehicles in accordance with the regulations.

Read recommendations:

DM11-050 Electric Magnetic Drill

CN21-1424 Nut Cutter丨Manual Integrated Nut Cutter

Alloy Saw Chains丨CC812/CC816 Series

Hydraulic wrench selection skills.Air impact wrench Processor

related articles

Using Chainsaws to Cut Snow?

2024-05-21What to do if the pneumatic wrench is weak

2022-12-19Hydraulic chain saw

2022-12-13Operation of the wrench

2022-12-06Introduction to the principle of pneumatic wrench

2022-11-28How to use the pneumatic wrench

2022-11-21Brief introduction to the principle of pneumatic wrench

2022-11-14Impact pneumatic wrench

2022-11-07Correct hydraulic wrench operation procedure

2022-11-01Hydraulic wrench torque pressure conversion

2022-11-01Field operation procedure of hydraulic wrench

2022-10-24Hydraulic radial plunger motor

2022-10-17The history of hydraulic motors

2022-10-17Principle of balance hydraulic wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Introduction to the advantages of using intelligent electric torque wrench

2022-10-10The Price Factor of Smart Electric Torque Wrench

2022-10-10Classification and use of wrenches

2022-10-10hydraulic wrench pressure conversion

2022-10-10Introduction to the advantages of the use of intelligent electric torque wrench

2022-10-10Smart Electric Torque Wrench Selection Guide

2022-10-10Intelligent electric torque wrench for wind power generation

2022-10-09Uses of open-end wrenches.Pneumatic chainsaw

2022-10-08What are the driving parts of a hydraulic wrench and what they do

2022-09-30What are the driving parts of a hydraulic wrench and what they do

2022-09-23the commonly used wrenches

2022-09-22Introduction of several common wrenches

2022-09-21Application scope and daily maintenance method of hydraulic bolt tensioner

2022-09-20Characteristics of hollow hydraulic wrench and precautions for use

2022-09-19Characteristics and precautions of driving hydraulic wrench

2022-09-17Power Tools

AN32-10000 Hollow Hydraulic Wrench

2023-06-27CB31-200 Hydraulic Band Saw

2023-06-16AN11-6000 Electric servo CNC Torque Wrench

2023-06-27CB61-200丨Emulsion Band Saw

2023-06-17LH61-032 Emulsion Hoist

2023-06-29CD31-500 Hydraulic Concrete Chainsaw

2023-06-16AN71-7500 Torque Multiplier

2023-06-29AW22-1200 Pneumatic Impact Wrench (Ultra-Light Series)

2022-12-20CD31-380 Hydraulic Concrete Chainsaw

2023-06-16RC21-850 Pneumatic Long Reach Scalers

2023-06-27AW21-4000 Pneumatic Impact Wrench (Ex-proof Series)

2022-12-19AW22-2000 Pneumatic Impact Wrench (Ultra-Light Series)

2021-06-15DM31-030 Hydraulic Magnetic Drill

2020-06-13RH21-1800 Pneumatic Chipping Hammer

2021-06-16CB31-120 Hydraulic Band Saw

2020-06-13RH21-1100 Pneumatic Chipping Hammer

2021-06-16AN51-6000 Electric servo CNC Torque Wrench

2023-06-27CB31-160 Hydraulic Band Saw

2023-06-16DM11-120 Electric Magnetic Drill

2023-06-19LH11-005 Electric Hoist

2023-05-11CR21-003 Light Pneumatic Reciprocating Saw

2021-06-07AN21-300 Pneumatic Nut Runner

2022-12-20RH31-1550 Hydraulic Chipping Hammer

2023-06-27DM31-035 Hydraulic Magnetic Drill

2022-12-30AN21-270 Pneumatic Nut Runner

2023-06-21LH61-020 Emulsion Hoist

2023-06-29AN22-4500 Pneumatic Torque Wrench (straight shaft)

2023-06-27AN32-5000 Hollow Hydraulic Wrench

2023-06-27DM21-023 Pneumatic magnetic drill

2021-06-15CC20-630 Pneumatic Chainsaw (3.0 kw Series)

2023-06-14Accessories

Filter assy.

2023-06-07Pipe Fixed Clamps丨CB861-12

2023-06-06Platform Clamps丨CB863-19

2023-06-06Regular Saw Chains丨CC811 Series

2023-06-06Ex-proof Sleeves KIT

2023-06-07Alloy Saw Blades丨CR812 Series

2023-06-06Diamond Saw Chains丨CC813 Series

2023-06-06Carborundum Saw Chains

2023-06-06Alloy Guide Bars丨CC814 Series

2023-06-06Chisels

2023-06-07Alloy Drill Bits丨811 Series

2023-06-06Carbide Inserts Twist Bits丨DB82 Series

2023-06-06Diamond Saw Blades

2023-06-06Grinding Disc

2023-06-07Alloy Saw Blades丨CR814 Series

2023-06-06Pin

2023-06-07Diamond Saw Blades

2023-06-06Split Hollow Drill Bits丨DC82

2023-06-07Diamond Saw Chains

2020-06-13Alloy Drill Bits丨813 Series

2023-06-06Abrasive Blades

2023-06-07Hydraulic Pump Station

2023-06-07Alloy Twist Drill Bits

2023-06-06Hydraulic Regulating Valve

2023-06-07Ex-proof Sleeves

2023-06-07Hard Alloy Hollow Drill Bits assy.丨DB85 Series

2023-06-07Carbide Hollow Bits丨DM816 Series

2023-06-06Core Drill Morse Taper Sleeves

2023-06-07Alloy Saw Blades

2023-06-06Tool Bits

2023-06-07

You are here: >

You are here: >